What Is To Be Considered In Chicken Layer Cage Design?

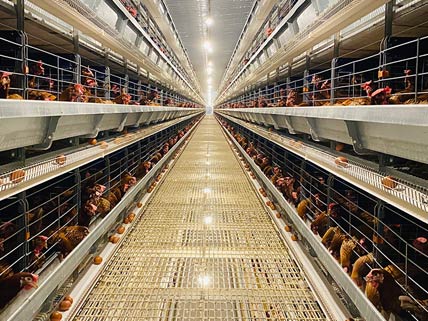

The layer cage is specially designed for commercial laying hens to maximize the number of eggs they produce. When the RTL chicken is moved from the chick cage to the layer cages, it is expected to keep the hens in high-quality chicken cages in a good chicken farm environment that has good ventilation, appropriate lighting, and temperature. To be specific, manufacturers of battery cages tend to focus on two important factors. One is the structure, and the other is the material.

Mandy Layer cage structure design

When designing the layer cages, the capacity of the cages is the first consideration in this intensive breeding method. Mandy optimizes the utilization of space and reserves enough moving space for each hen to avoid the crowd and fighting at the same time.

A type layer cage design

3 tiers 96 birds. 4 doors per tier with 4 birds per cell. One side 48 birds, two sides 96 birds.

3 tiers 120 birds. 5 doors per tier with 4 birds per cell. One side 60 birds, two sides 120 birds.

4 tiers 120 birds. 5 doors per tier with 3 birds per cell. One side 60 birds, two sides 120 birds.

4 tiers 128 birds. 4 doors per tier with 4 birds per cell. One side 64 birds, two sides 128 birds.

4 tiers 160 birds. 5 doors per tier with 4 birds per cell. One side 80 birds, two sides 160 birds.

H type layer cage design

3 tiers 120 birds. 4 doors per tier with 5 birds per cell. One side 60 birds, two sides 120 birds.

3 tiers 144 birds. 4 doors per tier with 6 birds per cell. One side 72 birds, two sides 144 birds.

3 tiers 54 birds. 1 door per tier with 9 birds per cell. One side 27 birds, two sides 54 birds.

4 tiers 160 birds. 4 doors per tier with 5 birds per cell. One side 80 birds, two sides 160 birds.

4 tiers 192 birds. 4 doors per tier with 6 birds per cell. One side 96 birds, two sides 192 birds.

4 tiers 72 birds. 1 door per tier with 9 birds per cell. One side 39 birds, two sides 72 birds.

5 tiers 240 birds. 4 doors per tier with 6 birds per cell. One side 120 birds, two sides 240 birds.

5 tiers 90 birds. 1 door per tier with 9 birds per cell. One side 45 birds, two sides 90 birds.

6 tiers 288 birds. 4 doors per tier with 6 birds per cell. One side 144 birds, two sides 288 birds.

6 tiers 108 birds. 1 door per tier with 9 birds per cell. One side 54 birds, two sides108 birds.

8 tiers 144 birds. 1 door per tier with 9 birds per cell. One side 72 birds, two sides 144 birds.

Mandy Layer cage material

Chicken cages made of different materials will have very different characteristics. Low-quality material will immediately jeopardize the profits of raising chickens. For example, the service life of the chicken cage, the quality of eggs, the rate of broken eggs, etc. are all related to the material of the chicken cage.

If the chicken cage material is easy to rust, the reason is that the humidity inside the chicken house is high, the rust rate of the chicken cage will be accelerated, and the service life will be shortened. If the chicken coop is rusted, the eggshell will be contaminated with rust, which will endanger the quality of the eggs. And if the wire of the chicken cage is not very elastic, it will also increase the egg breaking rate.

Mandy adopts Q235 bridge steel wire mesh with hot galvanized surface treatment or cold galvanized treatment. The material is anti-rust, sturdy, durable, and has good elasticity.

How to choose a reasonably designed egg layer cage?

From the number of chickens you raise

According to our years of experience, we suggest the A type layer cages for farm scales of 1-25000 chickens. If the number of chickens is above 25000, it is advised to choose the H-type layer cages.

From the budget you have

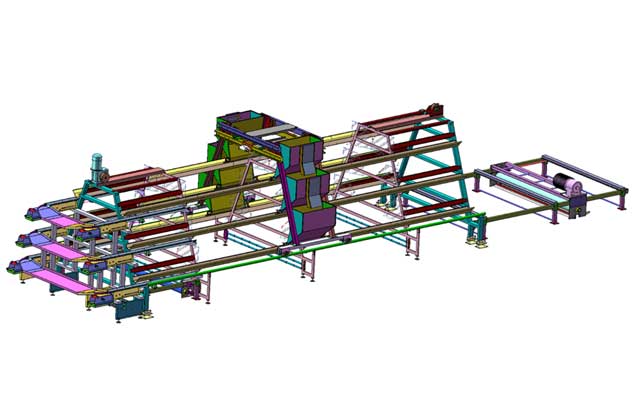

Mandy offers Both A type layer cages and H type layer cages to satisfy the different needs of chicken farmers. The A type layer cage saves cost in the perspective of related poultry farm equipment. Most of the equipment is not mandatory but optional such as the automatic belt manure cleaning system can be replaced by the scrapper machine, and the egg collecting machine can be replaced by a simply designed collecting platform. The H type layer cage can only be equipped with fully automatic systems to keep the large numbers of chickens living in a healthy, comfortable, and clean environment. To be specific, the automatic drinking systems, the automatic feeding systems, the automatic manure cleaning systems, and the egg collecting systems (advised).

Suggested related equipment for layer cages

1-5000 chickens. (A type designed layer cage)

We suggest that farmers choose A type layer cage and automatic drinking system only. If the budget is enough, the automatic manure cleaning equipment can be added. It is more cost-effective to use manual workers for egg collection.

5000-10000 chickens. (A-type designed layer cage)

We suggest that you use the cage with an automatic drinking system, automatic feeding system, automatic manure removal system, and the climate control system(except for the open chicken house ).

10000-25000 chickens. (A-type designed layer cage)

Since the scale of farming is larger and the work of egg collecting is time and energy-consuming, it is suggested to add the automatic egg collecting machine to your layer cage. Of course, the other automatic poultry farm equipment is also necessary.

25000 chickens and more. (H-type designed layer cage)

There is no controversy that farm scales beyond 25000 birds should be designed with H type layer cages and the fully automatic chicken feeding, drinking, manure cleaning, and the climate control system mainly including poultry exhaust fans and poultry cooling pads.

Rre

Rre

Post your divine reply